Highly Expandable Capabilities to Accommodate Practically Any Press Application

The stamping industry is constantly evolving its press production systems to be more productive in an increasingly competitive world. While manually-fed single presses are still a viable solution for short-run contract stamping, major stampers in the automotive, appliance, and other industries and their tier-1 and tier-2 suppliers have turned to sophisticated coil-and-transfer-feeding automation, scrap removal systems, and automatic or semi-automatic die change systems (such as rolling bolsters) to increase productivity.

Link intelligent press and automation control products are custom-engineered to increase safety and productivity for the simplest manually-fed mechanical power presses to the most sophisticated, automatic coil-fed presses or blank-fed transfer and tandem press productions systems.

Link controls for press production systems:

- Enable Highly Advanced Control With Almost Unlimited Expansion Capability

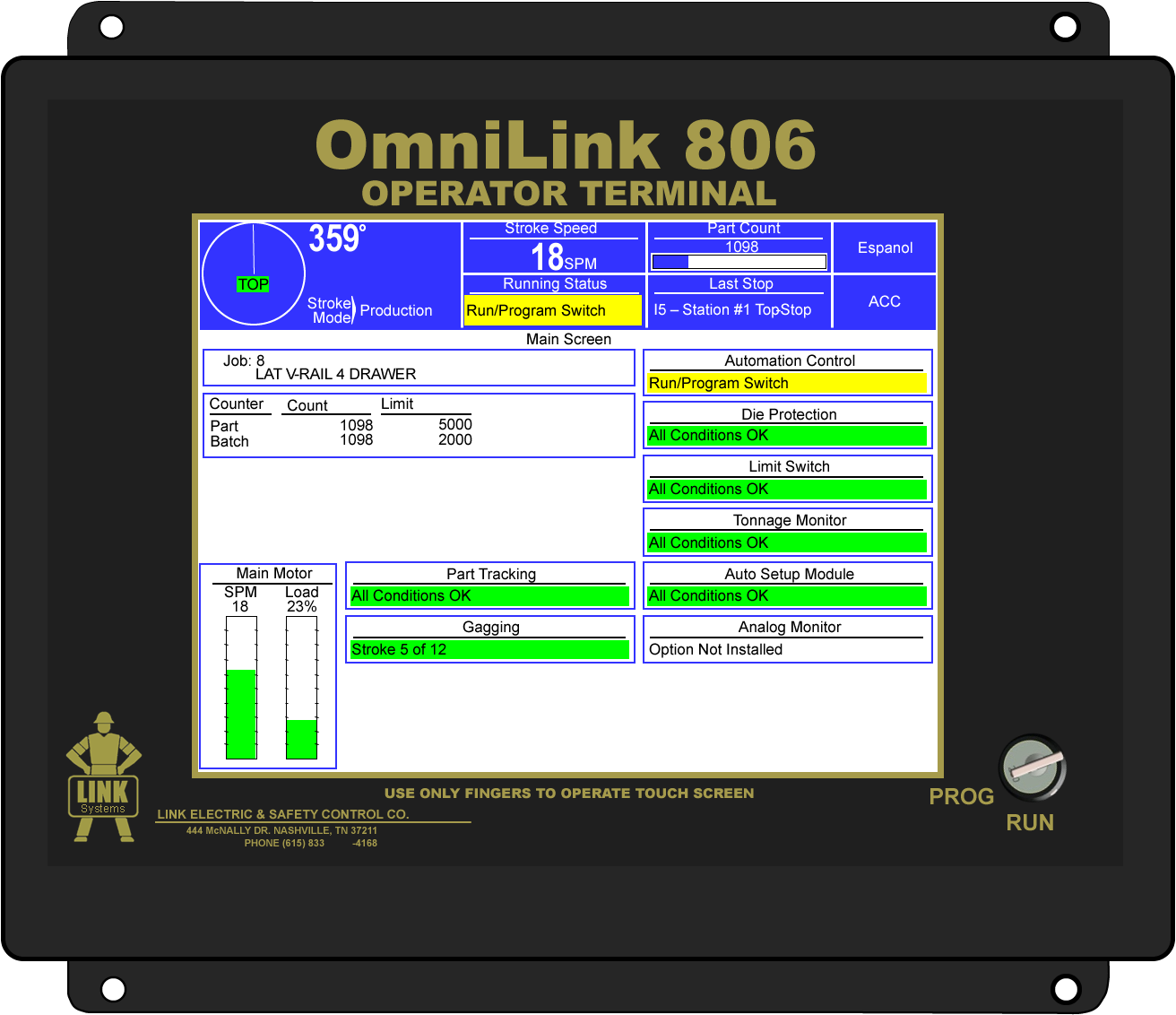

- Integrate With Press Control and Automation Monitoring, Sequencing, and Interface Through OmniLink Operator Terminals

- Reduce Changeover Time by Recalling Previously-Stored Job Settings

- Can be Expanded for Additional Functionality as Future Needs Arise

- Can Monitor and Protect Presses and Dies and Reduce Scrap

- Identify Productivity Issues With Intelligent Diagnostics

- Can Prevent Unauthorized Changes to Critical Settings

- Meet or Exceed All OSHA, ANSI, CSA, and Other Relevant Standards

Why Trust Link for Press and Automation Controls

With over 200 combined years of control experience in the metalforming industry, our team will custom-engineer and build the right solution for your press production system, whether simple or sophisticated. Link will provide industry-leading support to ensure it brings value to your operations for years to come.

Press and Automation Control Products

View our press and automation control options below to learn how we can engineer a highly configurable system to meet your present and future production needs.

For more detailed specifications on our Intelligent Press and Automation Control products: Download Product Comparison